knoop hardness test formula|knoop hardness test pdf : commercial The Knoop hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an . Do you want to join the hottest online community for social media girls fans? Check out the Social Media Girls Forum, where you can find and request exclusive content from your .

{plog:ftitle_list}

Resultado da 3,557 Gorda FREE videos found on XVIDEOS for this search. Language: Your location: USA Straight. Premium Join for FREE Login. Best Videos; Categories. Porn in your language; 3d; Amateur; Anal; Arab; Asian; ASMR; Ass; BBW; Bi; . 2 min Culona Gorda - 1080p. Sophia Fat Ass 37 sec. 37 .

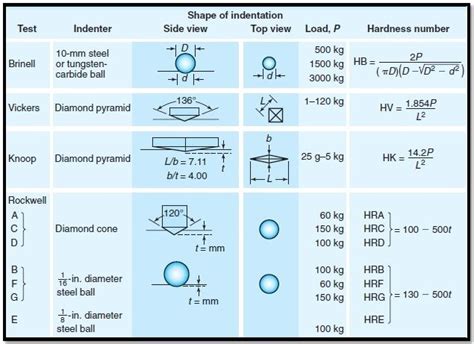

Knoop Hardness Test. The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a .The general principle of the Vickers and Knoop indentation hardness test consists of two steps: Step 1 - The applicable specified indenter is brought into contact with the test specimen in a .The Knoop hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an .The Knoop method has a test load range of 1 gf to 2 kgf according to ISO and ASTM, which means that this method can be used for hardness testing in the micro and low-load ranges. It is an optical method.

The Knoop hardness (HK) results from the quotient of the test force (F in newtons N) and the projection surface (surface area) of the indent, calculated using the longer diagonal (d in .The final Knoop hardness (HK) is derived from the following formula: HK = 14.229 (F / D2), with F being the applied load (measured in kilograms-force) and D2 the area of the indentation .

Hardness Calculation: The Knoop Hardness Number (HK) is calculated using the formula: \[HK = \frac{{1.8544 \times F}}{{d^2}}\]. Where \(F\) is the applied force in grams-force, and \(d\) is the length of the indentation .Learn how to use Knoop microhardness testers and testing machines to analyze the hardness of brittle and thin materials such as ceramics and coatings – with knowledge and insight from Struers, the world’s leading .

Differential Thermal Analyzer tv shopping

The Knoop hardness test method is one of the microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.The dwell time for the test force is 10 to 15 seconds (nominal time duration 14 s). If the dwell time is any longer, the duration in seconds must also be specified in the hardness value, e.g.: 870 HK 1/30 (dwell time of 30 s). The test forces used in the Knoop method are very small. Consequently, the indents are also very small.numbers shall be followed by the symbol HV for Vickers hardness, or HK for Knoop hardness, and be supplemented by a value representing the test force in kgf. Examples: 450 HV 10 = Vickers hardness number of 450 obtained with a test force of 10 kgf, 700 HV 0.1 = Vickers hardness number of 700 obtained with a test force of 100 gf (0.1 kgf), 500 .

The Knoop hardness test uses a rhombohedral-shaped diamond indenter. The long diagonal is seven times (7.114 actually) as long as the short diagonal. With the indenter shape, elastic recovery can be held to a minimum. The Knoop hardness test is conducted in the same manor, and the the same tester as the Vickers hardness test. However, only the .Knoop Hardness. The Knoop hardness is the measure of the Knoop hardness test, a micro-hardness test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes.However, Brinell, Rockwell, Vickers, Knoop, Mohs, Scleroscope, and the Files test are the most widely used hardness tests. In this article, we will learn about the Brinell Hardness Test, its procedure, related formulas, applications, advantages, and standards. . can be calculated using the following Brinell hardness test formula: Fig. 2 . See the description of the Knoop Hardness test below. The following equation is used to calculate Knoop Hardness number (HK): . For further information see [1]. . Hardness Test and Formula. Hertzian Calculator - Line Contact: Online. Hertzian Stress Calculator - Elliptical and Point Contacts: Online.

The test involves making a Knoop hardness indentation in the surface of a flexural bar, thereby forming a crack underneath the indentation site, removing the residual stressed zone surrounding the indent, and fracturing the bar in four-point bending. From: Handbook of Advanced Ceramics (Second Edition), 2013.

Knoop Hardness. The Knoop hardness is the measure of the Knoop hardness test, a micro-hardness test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes.

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . Knoop: The Knoop hardness test employs a rhombic-based pyramid-shaped indenter with a more elongated shape. Indentation Geometry. Vickers: The Vickers test creates a square-shaped indentation with well-defined corners. Knoop: The Knoop test creates an elongated, diamond-shaped indentation with one pointed end and one rounded end. .Brinell hardness test (HB) BHN and HBW are widely used [7] Knoop hardness test (HK), for measurement over small areas, widely used to test glass or ceramic material. [8] Janka hardness test, for wood; Meyer hardness test; Rockwell hardness test (HR), principally used in the USA. HRA, HRB and HRC scales are most widely used.Video explains what is hardness and different type of hardness tests such as Brinell, Vickers, Rockwell and Knoop. Brinell hardness test, Vickers hardness te.

The diagonals of the indent are measured optically in order to determine the hardness, using a table or formula. Used for hardness testing of all solid materials, including metallic materials . The Knoop hardness test. Knoop (HK) is an alternative to the Vickers test in the micro hardness testing range. It is mainly used to overcome cracking .

That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; . The Knoop hardness is calculated by the following formula: Knoop Hardness, HK = Applied test force in kilogram-force (kgf) ÷ Surface area of indentation (mm 2) or, HK = 14.229 x (F/D 2) Mohs Hardness Test. The . The Knoop hardness can be calculated from the diagonal size d of the indentation using the following formula: The standard ISO 9385 [1] describes the measurement procedure for glasses. In accordanc e with this standard, the values for Knoop hardness HK are listed in the data sheets for a test force of

The methodology of the Knoop hardness test is similar to the Vickers test with the exception of the indenter shape. A standard Knoop indenter is a rhombic-based pyramid which produces an indentation that has an ideal ratio between long and short diagonals . Knoop Formula: HK = P/AP = P/d2 c = 14229P/d2

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The Knoop hardness test is specified in this document for lengths of indentation diagonals ≥0,020 mm. Using this method to determine Knoop hardness from smaller indentations is outside the scope of this document as results would suffer from large uncertainties due to the limitations of optical measurement and imperfections in tip geometry.

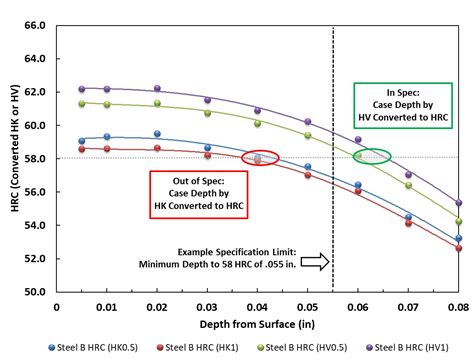

The measurements are converted to HV using a table or formula. Load range: From 10 gf up to 100 kgf; Play. . In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to .The Knoop hardness test uses a rhombohedral-shaped diamond indenter. The long diagonal is seven times (7.114 actually) as long as the short diagonal. With the indenter shape, elastic recovery can be held to a minimum. The Knoop hardness test is conducted in the same manor, and the the same tester as the Vickers hardness test. However, only the .5. Principle of Test and Apparatus 5.1 Vickers and Knoop Hardness Test Principle—The general principle of the Vickers and Knoop indentation hardness test consists of two steps. 5.1.1 Step 1—The applicable specified indenter is brought into contact with the test specimen in a direction normal to the surface, and the test force F is applied.

The Knoop and Vickers hardness numbers are designated by HK and HV, respectively, and hardness scales for both techniques are approximately equivalent. The Knoop hardness number HK or is given by the formula: Hardness Numbers and Conversion. There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell).

6. Test Specimen 6.1 The Knoop indentation hardness test is adaptable to a wide variety of glass specimens, ranging from tubing to television faceplates to polished plate glass. In general, the accuracy of the test will depend on the smoothness of the surface and, whenever possible, ground and polished specimens should be used.

When the mean diagonal of the indentation has been determined the Vickers hardness may be calculated from the formula, but is more convenient to use conversion tables. The Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was . Knoop test good for very hard brittle materials and very thin sections 4 .

knoop hardness vs rockwell

web30 de nov. de 2023 · Regarder Occupied City||2023|| Streaming VF, RegardezOccupied CityFilm Streaming VF, Telecharger TorrentOccupied Cityen France Torrent Gratuit.Occupied Citypeut être regarder pour vous inscrire gratuitement.

knoop hardness test formula|knoop hardness test pdf